Optimize Metal Casting with Advanced Simulation Software

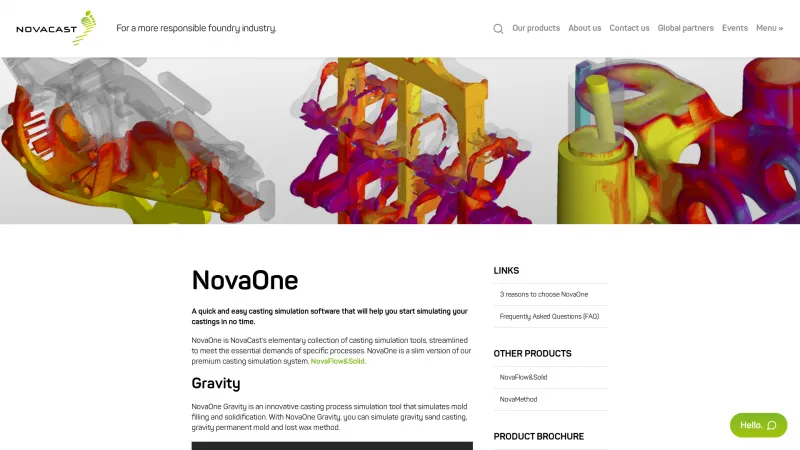

Casting simulation software is designed to optimize the metal casting process by providing detailed analysis and visualization of casting designs. This software addresses common challenges such as defects in castings, inefficient material usage, and lengthy production times. By simulating the casting process, users can predict potential issues like shrinkage, porosity, and thermal stresses before physical production begins. Read more

Key features of casting simulation software include advanced modeling capabilities, real-time analysis, and the ability to simulate various casting methods such as sand casting, die casting, and investment casting. These tools often incorporate features like flow simulation, solidification analysis, and thermal management, allowing engineers to refine designs and improve overall quality.

This software is best suited for foundries, manufacturing companies, and engineering firms involved in metal casting. Industries such as automotive, aerospace, and consumer goods benefit significantly from these tools, as they enhance productivity, reduce costs, and improve product quality. By leveraging casting simulation software, organizations can streamline their operations and achieve better outcomes in their casting projects.