Optimize Manufacturing with MRP Software Solutions

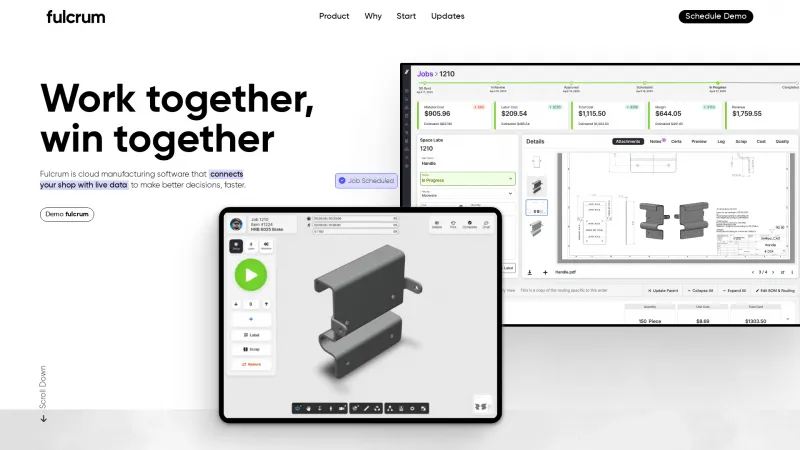

Material Requirements Planning (MRP) software is designed to streamline manufacturing processes by managing inventory levels, production planning, and scheduling. This software addresses common challenges such as overstocking, stockouts, and inefficient production schedules, ultimately enhancing operational efficiency. Read more

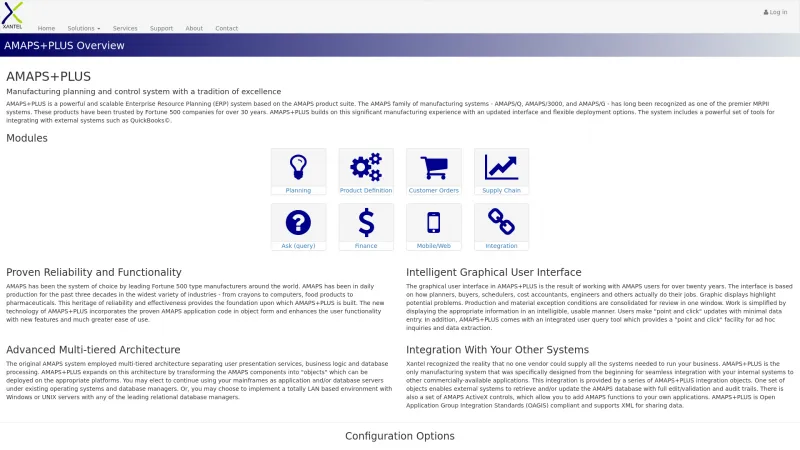

Key features of MRP software include demand forecasting, inventory tracking, production scheduling, and reporting tools. These functionalities enable businesses to optimize their supply chain, reduce waste, and improve order fulfillment rates. By automating these processes, MRP software helps organizations maintain the right amount of inventory, ensuring that materials are available when needed without excess.

MRP software is best suited for manufacturers, distributors, and supply chain managers across various industries, including automotive, electronics, and consumer goods. It is particularly beneficial for companies looking to improve their production efficiency, reduce costs, and enhance overall productivity.